Thaum tshav kub kub hloov rojyog ib hom roj tshwj xeeb nrog zoo thermal stability siv rau indirect tshav kub hloov.Thaum tshav kub kub conduction roj tsis tau tsuas yog ua tau raws li cov cua kub thiab txias txheej txheem yuav tsum tau ntawm cov kub sib txawv nyob rau hauv ib tug dav ntau yam ntawm qhov kub thiab txias, tab sis kuj paub txog cov txheej txheem yuav tsum tau ntawm kub kub thiab kub tsis txias txias nrog tib lub tshav kub conduction roj nyob rau hauv tib lub cev, uas yuav tsum tau. txo qhov nyuaj ntawm qhov system thiab kev ua haujlwm.Yog li ntawd, cov cua kub conduction roj cua sov system yog dav siv nyob rau hauv chemical fiber, khoom thiab lwm yam lag luam.

Cov yam ntxwv ntawm tshav kub conduction roj system:

1.Nyob rau hauv cov xwm txheej ntawm yuav luag atmospheric siab, tuaj yeem tau txais kev ua haujlwm siab heev - uas yog, tuaj yeem txo qis kev khiav hauj lwm siab thiab kev nyab xeeb ntawm cov cua kub cua sov, txhim kho kev ntseeg siab ntawm lub cev thiab cov khoom siv;

2.Lub tshav kub ua cov roj cua sov qhov system tshem tawm cov kev kho dej thiab cov khoom siv, uas txhim kho cov thermal efficiency ntawm lub cev thiab txo cov kev ua haujlwm ntawm cov khoom siv thiab cov kav dej - uas yog, thawj zaug peev thiab cov nqi khiav lag luam ntawm cov cua sov tuaj yeem ua tau. txo.

Muaj peev xwm txaus ntshai ntawm thermal roj system kev ua haujlwm:

1.Vim lub zos overheating ntawm lub cua sov system thaum lub sij hawm siv cov cua kub ua cov roj, thermal cracking cov tshuaj tiv thaiv yog nquag tshwm sim, uas ua rau volatile thiab tsawg flash point oligomers.Polymerization ntawm oligomers ua rau insoluble thiab insoluble polymers, uas tsis tsuas yog cuam tshuam cov ndlwg ntawm cov khoom roj thiab txo cov thermal conduction efficiency, tab sis kuj ua rau muaj peev xwm ntawm lub zos overheating deformation thiab tawg ntawm cov kav dej.

2.Heat hloov roj thiab yaj huab cua thiab cov khoom siv hluav taws xob ua kom sov yog cov tshuaj tiv thaiv oxidation ntawm cov huab cua seem nyob rau hauv cua sov, thiab tsim cov organic acid thiab colloid adheres rau cov roj pipeline, uas tsis tsuas yog cuam tshuam rau lub neej kev pab cuam ntawm tshav kub hloov nruab nrab thiab thaiv cov raj xa dej, tab sis kuj yooj yim ua rau cov kua qaub corrosion ntawm cov kav dej thiab ua rau muaj kev pheej hmoo ntawm kev ua haujlwm ntawm lub cev.

Cov xwm txheej ntawm tshav kub hloov roj cua sov system muaj xws li:hluav taws kub ntawm thermal rwb thaiv tsev txheej, hluav taws kub ntawm expansion tank tso tawm thiab thermal rwb thaiv tsev txheej, hluav taws kub ntawm tshav kub hloov roj system chaw ua hauj lwm, hluav taws kub thiab tawg ntawm tshav kub hloov roj tank, hluav taws kub thiab tawg ntawm tshav kub hloov roj kub exchanger los yog reactor (kub), cub tawg tawg, thiab lwm yam. Nws tuaj yeem pom tau tias ntau qhov kev sib tsoo ntawm cov roj cua kub cua sov ua rau muaj kev sib tsoo ntau dua los yog tsawg dua los ntawm kev xau.

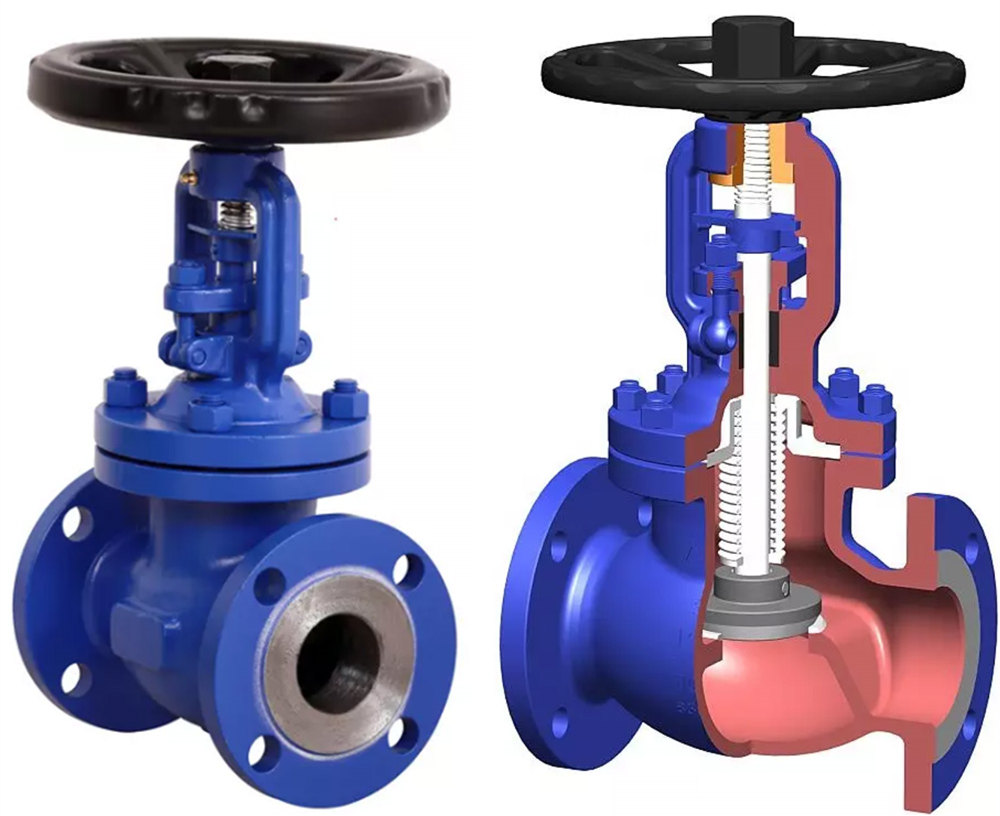

Valve yuav tsum tau rau tus qauv kev thiab tsim specifications nyob rau hauv cov roj kub systems muaj xws li: an tso valvenyob rau ntawm qhov chaw siab tshaj thiab ib lub tshuab blowdown ntawm qhov qis tshaj.Cov yeeb nkab kab ntawm cov roj kub system yuav tsum tau txuas nrogflangestshwj tsis yog rau ntaus ntawv interfaces, ntsuas interfaces lossis li qub.Tag nrho lwm yam interfaces yog welded.Covflangeyuav tsum tau teem lub zawj nto, thiab lub nominal siab yuav tsum tsis txhob tsawg tshaj li 1.6MPa.Rau tshav kub conduction roj nrog kub siab tshaj 300 degrees, lub nominal siab ntawm lubflangeyuav tsum tsis pub tsawg tshaj 2.5MPa.Flangesyuav tsum tau pob tw welded es tsis txhob tiaj welded flanges.Lub flange gasket ntawm cov roj kub tsis pub siv cov roj hmab asbestos, hlau winding ncoo lossis nthuav graphite composite ncoo yuav tsum tau siv.Cov roj kub kub yuav tsum tau muab nrog lub valve kev nyab xeeb, thiab kev nyab xeeb valve yuav tsum yog lub tshuab kaw kev ruaj ntseg valve.

Cov khoom siv ntawm cov roj kub kub yuav tsum tsis txhob cam khwb cia hlau lossis hlau tsis muaj hlau.Xav txog nws qhov tsis tshua muaj siab, kub siab thiab permeability yog qhov tshwj xeeb tshaj yog muaj zog, raws li tus qauv kev tsim qauv tshwj xeeb, cov roj kub lub raj xa hluav taws xob yuav tsum siv lub tshuab foob txiav tawm valve, kev tswj lub valve yuav tsum siv lub tshuab foob lub tes tsho regulating valve, kev ruaj ntseg valve siv. tag nrho qhib bellows foob kev nyab xeeb valve.

Vim tias cov yam ntxwv ntawm oxidation stability ntawm cov roj hluav taws xob hluav taws xob, cov hluav taws xob ntawm cov roj kub kub yuav tsis tsuas yog ua rau cov hluav taws xob hluav taws xob los yog cov khoom siv hluav taws xob tawg, tab sis kuj ua rau oxidation cov tshuaj tiv thaiv ntawm tshav kub conduction roj thiab cov cua yaj hauv cov khoom siv. rooj plaub ntawm tshav kub, tsim cov organic acid corrosion valve internals.Yog li ntawd, cov roj kub kub yuav tsum tsis yog tsuas yog tsis muaj qhov nkag mus rau sab hauv, tab sis kuj tsis muaj qhov to sab nraud.

General packing globe valve packing los ntawm graphite processing molding, yog hais tias lub purity ntawm graphite tsis txaus, nws cov roj kuj yuav ua tsis zoo, thaum tshav kub conduction roj rau hauv lub graphite packing, ib co impurities nyob rau hauv lub graphite yog ib qho yooj yim kom yaj los ntawm tshav kub conduction. roj, ua rau graphite hmoov, tsis tuaj yeem ua rau cov graphite packing kom ua tiav sealing nyhuv, qhov no yog lub ntsiab ua rau packing valve feem ntau to.Lub foob foob tiv thaiv kev sib cuag ncaj qha ntawm cov roj kub thiab graphite, uas daws qhov teeb meem ntawm cov roj kub los ntawm cov qia thaum lub graphite packing yog yaj.

Vim tias cov roj permeability ntawm cov roj hluav taws xob muaj zog heev (txog 50 npaug ntawm lub zog), yog tias lub foob raug xaiv, nws yooj yim heev kom xau tawm, ua rau pov tseg cov roj kub, cov khoom qias neeg thiab hauv av, thiab cov qauv hauv qab. tuaj yeem paub txog xoom xau, thiab tsis muaj qhov hnav.

Vim tias muaj peev xwm txaus ntshai ntawm oxidation stability ntawm cov roj hluav taws xob hluav taws xob, cov khoom siv sab hauv ntawm lub valve yog ua los ntawm cov hlau tsis muaj steel, uas tuaj yeem tiv taus 425 ℃ siab kub, tiv thaiv corrosion, thiab qhov hloov tau yooj yim tshwj xeeb.

Los ntawm tag nrho lub neej txoj kev xav, kev pab lub neej ntawm tus generallub cev sealing valveyog zoo dua li lwm yam li qub.Cov roj hloov hluav taws xob muaj cov viscosity siab thiab cov dej ntws loj hauv lub xeev txias.Cov tub ntxhais valve txais yuav hom qhib ceev, uas tuaj yeem txhim kho tus nqi ntws thiab kov yeej cov dej ntws zoo thaum pib.Yog li ntawd, txhawm rau ua kom muaj kev ruaj ntseg ntawm kev tsim khoom, tab sis kuj txhawm rau txo cov nqi khiav lag luam tiag tiag, lub tshuab hluav taws xob hloov hluav taws xob yuav tsum xaiv qhov ceev qhib valve tseem ceeb ntawm lub tshuab hluav taws xob.bellow foob nres valve, tsis tuaj yeem xaiv lub ntim ntim nres valve lossis lub valve dav dav.

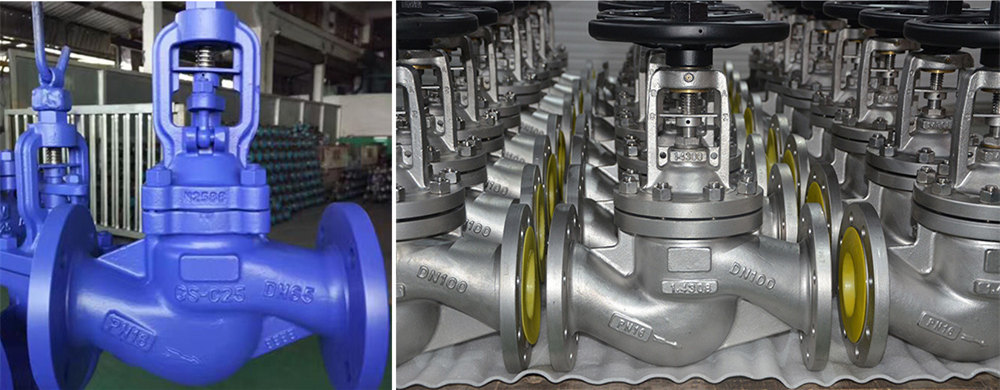

Bellows sealing ntiaj teb valveua los ntawm BESTOP yog qhov tsim nyog heev rau kev txiav cov kav xa dej ntawm cov roj kub kub.

Post lub sij hawm: Jan-29-2023